Our Expertise

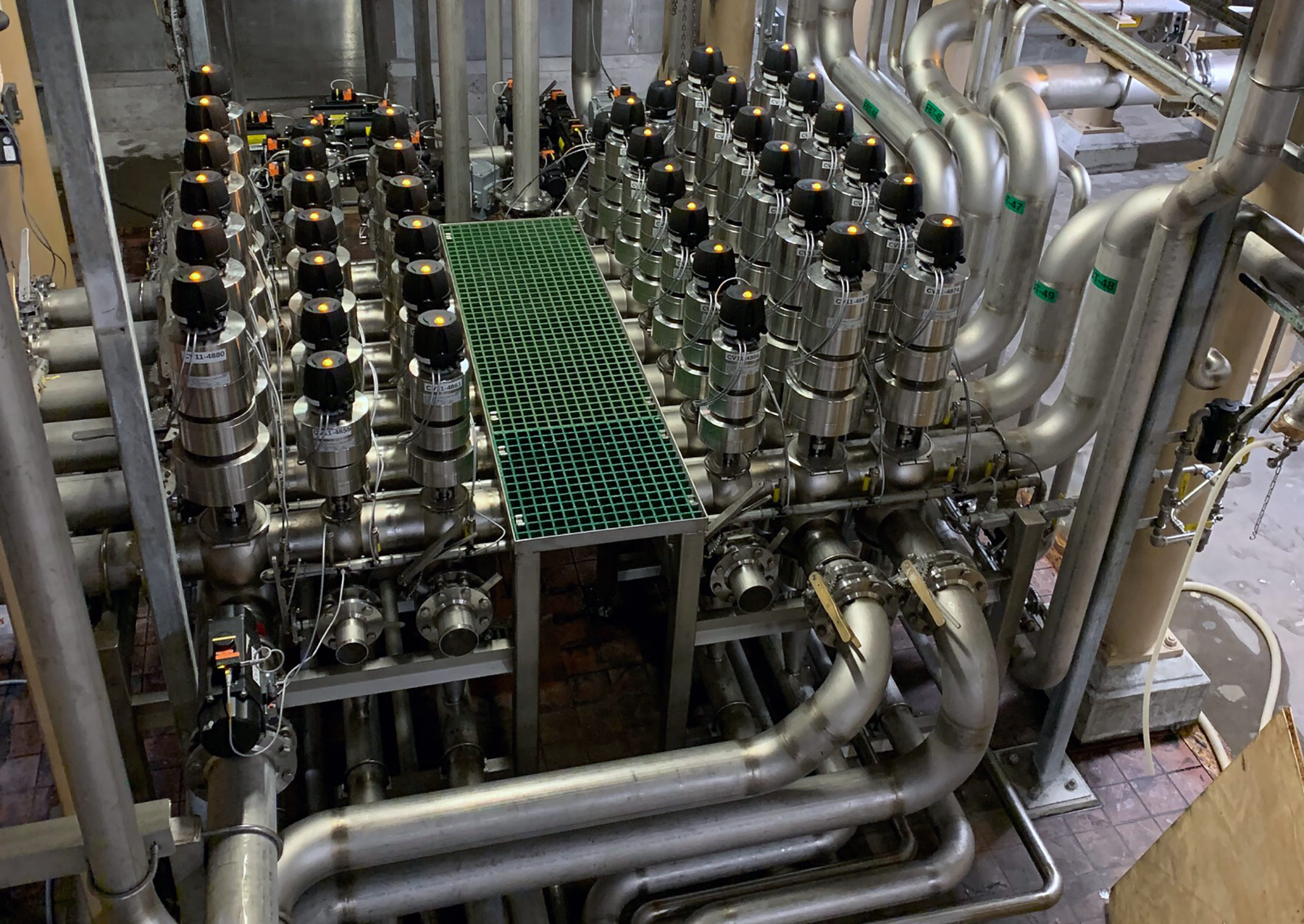

Process and High/Ultra High Purity Piping systems installation and maintenance requires an unparalleled level of expertise and experience. Burns Bros is the regional leader in process systems installation. Our experience is vast in the food and beverage, pharmaceutical, and advanced technology markets for major multi-national clients with the most stringent standards. We have an ISO-6 certified cleanroom within our fabrication facility, one of the very few in the Northeast.

Our in-house cleanroom manufacturing capabilities, coupled with investments in BIM, allow for the highly controlled off-site manufacture of high-purity systems under strictly controlled conditions.

Orbital

We have the capability to equip any size project with 5 Swagelok orbital weld machines in our inventory. With our multiple weld heads and collets, we can weld ¼” through 4” stainless steel tubing with seamless production. All power supplies are inspected annually to ensure the highest quality repeatable welds.

TIG

Stainless steel TIG welding is critical in the brewery industry. Burns Bros has the capability to outfit your project with trained, certified welders and pipefitters who understand the unique challenges associated with brewery process piping.

We understand the demanding nature and have worked effectively in the high purity piping market. Whether constructing a new facility or retrofitting an existing, Burns Bros is competent and capable to satisfy these technical installations, including:

- High Purity Water Systems

- Chemical Distribution

- Specialty Gas Systems

- Specialty & Solvent Waste Systems

Process and High Purity Piping

Process and High Purity Piping